Streamline your production processes with Odoo Manufacturing apps

Integrated, efficient, and designed to optimize every step of your manufacturing workflow

PLM (Product Lifecycle Management)

PLM (Product Lifecycle Management)

The Odoo PLM app simplifies product lifecycle management, allowing businesses to efficiently oversee product evolution from design to manufacturing.

With real-time collaboration tools, version control, and seamless integration with engineering workflows, teams can manage Bills of Materials (BoMs), track engineering change orders (ECOs), and ensure smooth communication across departments.

Odoo PLM helps eliminate redundancies, improve productivity, and foster innovation by unifying your processes on a single, user-friendly platform.

Purchase

Purchase

Odoo Purchase empowers manufacturing businesses with a seamless procurement process tailored to production needs.

Automate purchase orders based on inventory levels or production schedules, ensuring you have the right materials at the right time.

With supplier management, pricing comparisons, and integrated analytics, Odoo Purchase streamlines vendor relationships and cost efficiency.

Fully integrated with Odoo Manufacturing and Inventory, it delivers end-to-end visibility and control, enabling manufacturers to meet production demands with precision and agility.

Manufacturing

Manufacturing

Odoo Manufacturing app is a comprehensive solution tailored to streamline and optimize your production operations.

Designed for efficiency, it enables businesses to manage manufacturing orders, track work orders, and oversee the entire production process with ease.

From scheduling and automating work centers to tracking real-time production data and managing bills of materials, the app provides a centralized platform to enhance productivity.

With features like quality checks, maintenance alerts, and integrated inventory management, the Odoo Manufacturing app ensures seamless coordination across departments, reducing errors and boosting efficiency.

Whether you're looking to scale production, improve traceability, or automate workflows, the Odoo Manufacturing app helps you achieve operational excellence.

Quality

Quality

Ensure seamless quality control in your manufacturing processes with the Odoo Quality app.

This powerful tool allows you to define quality checks, set control points, and automate inspections at every stage of production.

With real-time tracking, customizable quality alerts, and integrated reporting, manufacturers can proactively detect issues, minimize defects, and maintain consistent product standards.

Enhance efficiency, comply with industry regulations, and deliver excellence with Odoo's comprehensive quality management solution.

Maintenance

Maintenance

Odoo Maintenance App is a powerful tool designed to streamline maintenance operations in manufacturing environments.

It enables proactive management of equipment and machinery, reducing downtime and ensuring optimal performance.

With features like preventive maintenance scheduling, automated alerts, and real-time tracking, the app helps manufacturing teams anticipate issues before they escalate.

Seamlessly integrated with Odoo's Manufacturing module, the Maintenance App enhances productivity by providing actionable insights, minimizing disruptions, and maximizing the lifecycle of assets.

Simplify your maintenance processes and keep your production running smoothly with Odoo!

Features to support your manufacturing

Manage

- Manufacturing orders - Manage your products into assembly lines or manual assembly.

- Work orders - Launch production of items needed in the final assembly of your products.

- Barcodes - Use barcode to speed up your manufacturing operations: lot or serial number scanning, start/pause/stop stopwatch, trigger a maintenance request, move to the next step, etc.

- Repair orders - Manage repairs of items under warranty or as a service.

- Editable MOs - Consume other products despite what was initially planned and edit MOs once they are done.

-

Unbilled orders - Disassemble a finished product and recuperate components.

Schedule and Plan

- Plan manufacturing - Get a clear view on your whole planning and easily reschedule manufacturing.

- Organize work orders - Have access to all available resources and plan ahead with your production.

- Manage Bill of Materials - Keep track of availability of items in stock and production time.

- Work center capacity - Use the MRP Scheduler to schedule your work at each work center, based on their OEE and capacity.

Master Data Management

- Create multi level BoMs - Set a Bill of Materials within another in order to manufacture components of a product in another Bill of Materials.

- Optional routing - Create new routings for work orders in order to sequence your production depending on the routing used.

- Version changes - Allow your products to evolve and add configurable options when creating orders.

- Kits - Using the Kit feature, your salesperson will be able to sell products that will be delivered as a set of components to assemble.

PLM

- Versioning - Easily get differences between versions to track changes.

- PLM - Track versions of products and ECO's as well as their respective documents. Merge different ECO's corresponding to the same BoM.

- Engineering changes - Track changes with a great kanban process for ECOs.

- Document management - Store plans and worksheet directly on bill of materials and routings.

Workcenter Management

- Set tablets on every work center to organize their work efficiently.

- Register productions, scan products, lots or serial numbers.

- Display worksheets directly on the work center with instructions for the operator.

- Scrap products, create quality alerts, perform checks, right from the work center.

- Use alerts to show changes or quality checks to the operator.

-

Define multiple steps in a work order and link them to worksheet pages: scan a product, take a picture, quality control, etc.

Maintenance

- Preventive maintenance - Trigger maintenance requests automatically based on KPIs.

- Corrective maintenance - Trigger corrective maintenance directly from the control center panel.

- Calendar - Schedule maintenance operations with a calendar.

- Statistic - Get all maintenance statistics computed for you: MTBF.

Reporting

-

Get a full upstream traceability report on the components used during the manufacturing process

-

Track the cost of each manufacturing order based on the cost of the components and on the cost of your operations (labor or material).

-

Analyze your work centers loads, the productivity losses and track your overall equipment effectiveness (OEE)

Quality

-

Control points - Automatically trigger quality checks for the manufacturing department.

-

Quality checks - Deploy your statistical process control easily with checks.

- Quality alerts - Organize your work using the kanban view of quality alerts.

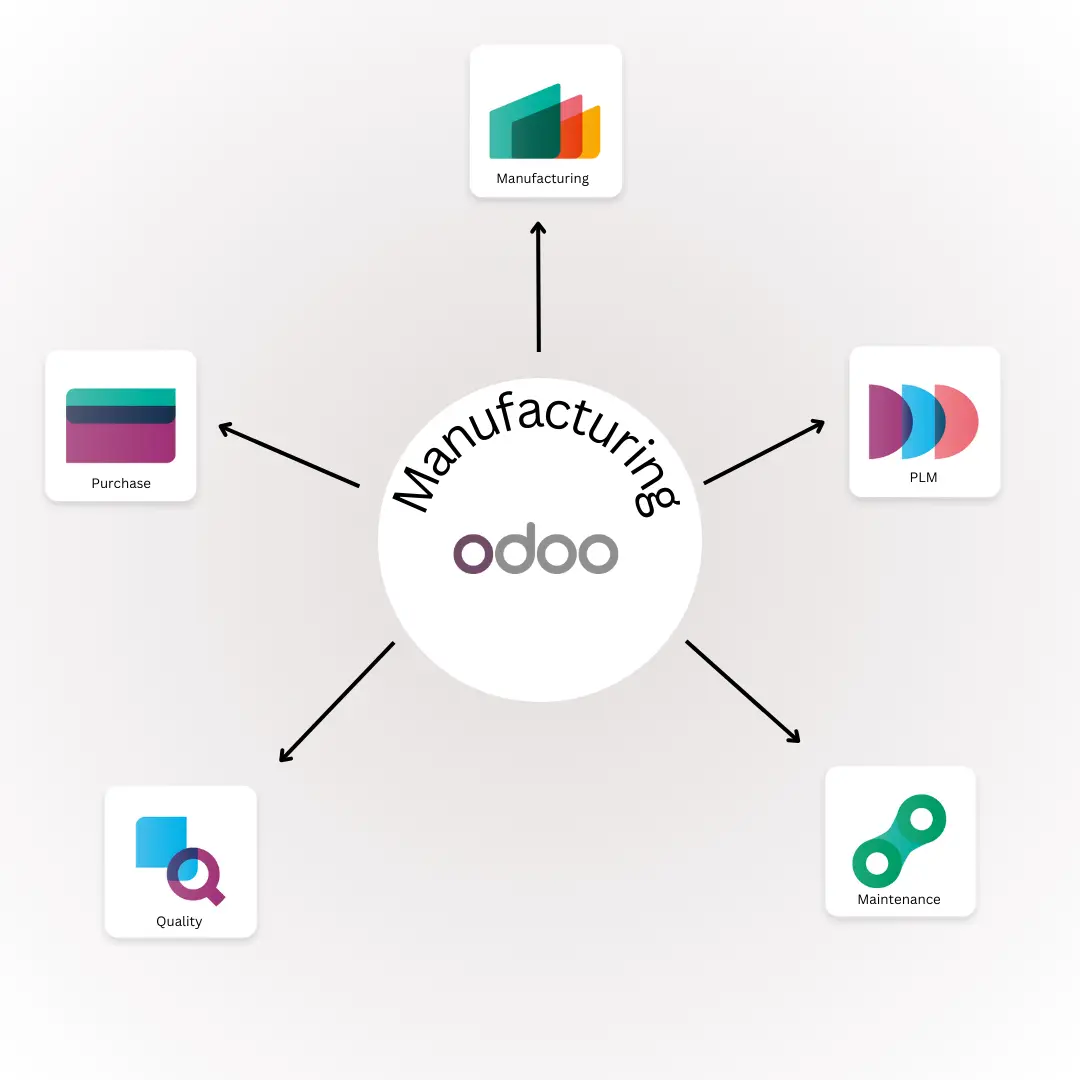

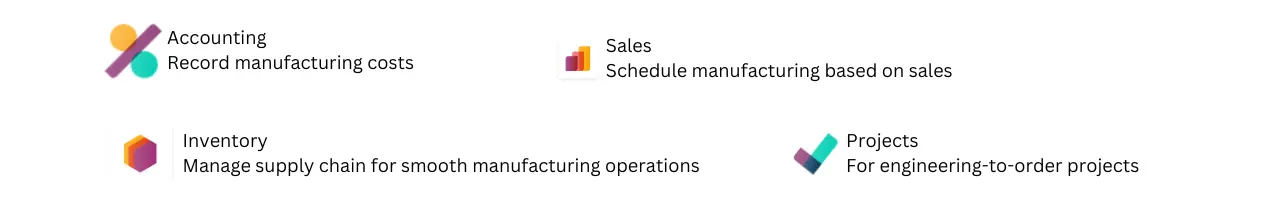

Seamless integration with other operations

Expand as you grow. Simple and fast integration with other Odoo apps

12 Million+ users world-wide trust Odoo

Simulate manufacturing orders, Schedule and plan resources, Record production and components, IoT integration, Manage engineering changes and much more...

Contact us